GPH Ispat cares for environment while making steel

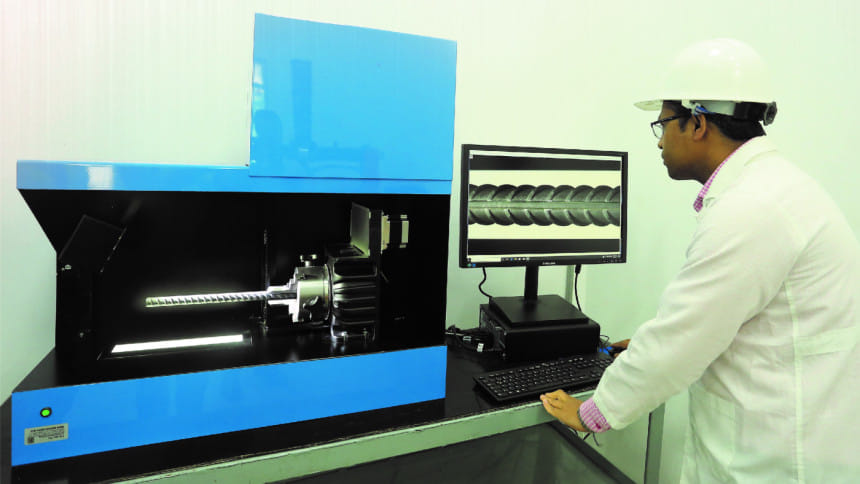

Commitment to safeguarding the environment was the top priority of Bangladesh's leading steelmaker GPH Ispat when it went for a large investment to establish Asia's first quantum electric arc furnace technology-based plant, a cutting-edge technology in steel making.

The steelmaker initiated the massive expansion plan in 2016 and invested Tk 2,390 crore to establish the state-of-the-art plant, which is the second of its kind in the world.

The first such plant was established in Mexico.

GPH Ispat Executive Director for Marketing and Sales Shobhon Mahbub Shahabuddin shared the information during a recent interview with The Daily Star.

After facing a delay of one and a half years, commercial production at the plant of Chattogram-based GPH Ispat began in June this year, Shahabuddin said.

The new plant has a capacity to produce 8.40 lakh tonnes of mild steel (MS) billet annually while its old plant with traditional induction furnaces had melting capacity to produce 1.70 lakh tonnes of billet, he said.

Equipped with the newly adopted technology, the combined billet making capacity of GPH Ispat has crossed 1 million tonnes per year, the executive director said.

The new plant also has expanded the steelmaker's MS rod producing capacity, adding an additional 6.40 lakh tonnes a year to the already existing 1.50 lakh tonnes rolling capacity from its previous plant.

But, enhancing production capacity or ensuring best quality products to lead the market was not the only goal behind such big investment, the manufacturer actually visioned for environmental sustainability while setting up the completely green and world-class plant.

"In our part of the world, many manufacturers did not invest in environment, but we chose to because saving the environment is the top priority that is held very close to the heart by the owners of GPH, the whole GPH family."

"All of us, who work here in any capacity, are always encouraged, are always informed and are given the direction to work in such a manner that the principles that we hold dearly in our hearts to protect the environment are never compromised," he said.

"That is something that we do consciously and take a great deal of pride in. We hope to continue in a manner that will show the rest of the manufactures in Bangladesh, to the whole world in fact, that it's possible to become top notch steel manufacturer without causing harm to the environment," the executive director said.

The advanced technology enables the company not only to produce highest quality construction steel but also the purest steel since all the impurities can be removed, he said.

This technology with its different features helps the company avoid causing any harm to the environment, claimed the GPH Ispat official.

Firstly, the company's quantum furnace technology-based plant ensures production of high quality steel products with less energy.

The furnace creates a huge amount of heat at the time of melting the scrap of a batch.

GPH Ispat's technology uses this heat to preheat the next batch of scrap stored in a basket on top of the earlier batch.

"The benefit of the preheating is that the already preheated scraps get melted comparatively in a lower temperature, thus it saves energy. That heat otherwise would go to waste."

Secondly, the quantum green factory has highly sophisticated and advanced exhaust gas purification system to keep the environment clean.

Thirdly, emission of carbon and dust from the factory is currently less than 5 milligram per cubic metre, which is 90 per cent less than the standard of 50 mg per cubic metre set by the World Bank.

It is also 98 per cent less than the standard of 350 mg per cubic metre set by Bangladesh's Department of Environment.

It enables the company to reduce natural gas consumption about 35 cubic metre per tonne against existing steel production practices in the country.

Another feature is that it has a strong evacuation system that helps all the pollutants, including the gaseous ones, to be removed within the system and they are not released into the factory floor, he said.

The company has taken several other steps to support its commitment to save the environment.

The oxygen plant GPH set up in its factory is 'the largest in the country', which produces 225 tonnes of gaseous oxygen and 25 tonnes of liquid oxygen daily, he said.

GPH Ispat has so far distributed more than 1,000 oxygen cylinders to different hospitals and it keeps on refilling about 150 cylinders every day since the beginning of the coronavirus pandemic.

GPH Ispat is the only factory in the country that has its own water harvesting system and water treatment plant with zero discharge technology.

"An artificial lake has been built where rain water is preserved and harvested enabling us not to use underground water for the plant anymore," Shahabuddin said.

Rainwater harvesting through catchment provides 2,500 cubic metres of water a day and thus helps saving that much of underground water, he said.

The company also harvests rainwater on the rooftop reservoir during rainy season thus saving almost 1,000 cubic metres of water per day.

Moreover, the zero-discharge technology of the water treatment plant helps treating the water that is used in the plant and that water is recycled into the main water circulation system.

All these features of the advanced technology and the supporting steps have made the plant green and environment-friendly, which are rarely seen in Bangladesh or in the neighbouring countries, he said.

"We could set up a normal arc furnace based plant and then we would be better off financially. Because of the commitment of safeguarding the environment, we have invested heavily in these causes," he said.

GPH Ispat is indeed a commercial institution and it needs to make a profit, he said.

"We aspire to be the number one steel maker in Bangladesh in the near future and we are trying all that we can do to achieve that along with never neglecting our commitment to safeguard and preserve the environment."

Coronavirus pandemic has badly hit the steel market as well as the projected sales of GPH Ispat, but the company managed to maintain a healthy double-digit growth in sales year-on-year, Shahabuddin informed.

The company is trying to recover the challenges of this pandemic.

"We think if we can just survive this pandemic maintaining the current growth rate, the practices we would have developed in the interim period will pay us big dividends in the future."

In 2019, GPH Ispat had a market share of around 7 per cent of the country's MS rod market.

The executive director expects its market share to be around 10 per cent by the end of this year.

The pandemic is restricting the company to utilise its full production capacity. The projected sales of MS rod of both of its factories may reach 4.80 lakh tonnes in the current year.

Expressing his satisfaction over the sales growth, Shahabuddin hoped that within a year and a half the plant would be able to produce at its full capacity.

For all latest news, follow The Daily Star's Google News channel.

For all latest news, follow The Daily Star's Google News channel.

Comments