Major flaws in 10 garment factories

Engineers hired by European brands and retailers have identified major electrical and structural flaws in 10 leading local garment factories in their first scrutiny under a five-year aggressive inspection plan.

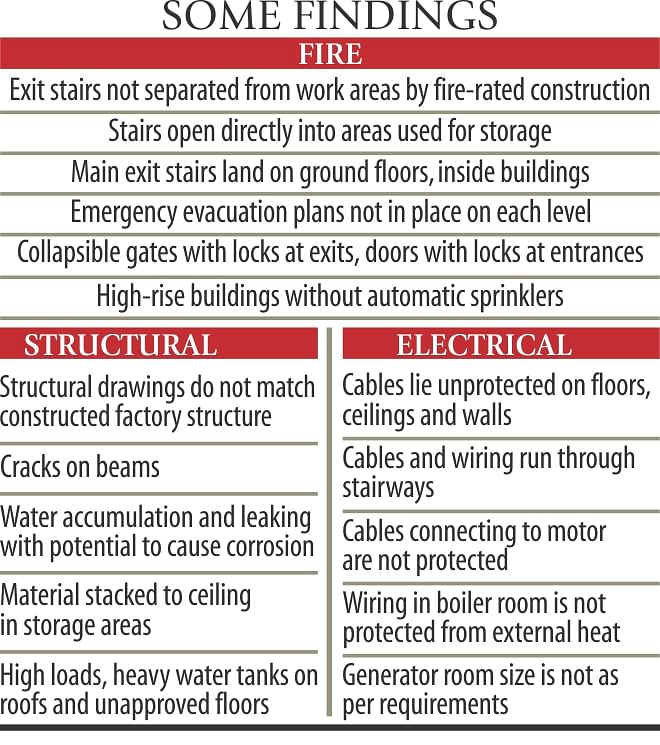

The teams from the Accord on Fire and Building Safety in Bangladesh detected electrical safety problems as cables were found laid down on the floor without proper safety, said Rob Wayss, its executive director, in an example of the type of flaws.

At a press conference at Best Western La Vinci Hotel in Dhaka, he said cables entering or leaving the terminal box are connected without cable gland and baseplate.

Brad Loewen, chief safety inspector of the Accord, a platform of 150 retailers and brands mainly from Europe, said cables are laid directly on concrete floor.

The inspection teams also found overloading of goods on different floors in factory buildings, insufficient exit capacity through the exit doors and absence of sprinklers. Loewen showed a photograph of dozens of electric wires entangled on a factory floor.

The safety picture of garment factories came after the Accord under a pilot project inspected Alif Garments, Big Boss Corp, Anlima Textiles, Dragon Sweater, Grameen Knitwear, Majumder Fashions, Redpoint Jackets, Rio Fashion, Fashion Island and Viyellatex in late 2013.

Wayss said the findings are similar as the problems are also similar in almost all the inspected factories.

However, the Accord formally started safety checks from February 20.

Of the 68 factories it inspected so far, two were temporarily closed last week after serious structural flaws were detected, although work was allowed to continue in one factory after its load was reduced.

Wayss said the initial inspection programme is running in full swing at the moment and would continue through September this year.

About 250 factories will be inspected each month as per its plan to inspect all of its 1,500 supplier factories. The inspections have started with the high-risk buildings that have more than five floors.

Wayss said the Accord is working intensively with brands, labour unions, factory owners, industry associations and the labour ministry so they understand the Accord's commitment and responsibility to make the inspection and remediation programme a success.

"Safe factories benefit everyone. They obviously benefit workers, employees, factory managers, owners, the industry and ultimately the country."

On the payment to workers for any production suspension caused by the inspection, the Accord chief said the factory owners, not the retailers or brands, are responsible for such payments.

Brands may help find funding if the owners need assistance in addressing safety issues raised by the inspectors, he said.

Wayss said a process is underway to recruit 25 fulltime Bangladeshi engineers to be engaged with the foreign engineers.

Currently, 60 foreign engineers are working and 52 Bangladeshi nationals are assisting them. Loewen said notice will be issued to factories two weeks before the inspection begins. After the inspection, the owner will discuss remediation with the representatives of buyers.

He said they would publish reports on the inspections and there will be follow-up visits to check whether the problems were fixed.

“After the initial inspection, we will monitor the improvements in the next five years,” Loewen said. "It's an aggressive plan."

On making garments in shared factory buildings, Wayss said retailers might be concerned about it, but the Accord did not prohibit any owner from doing so. On the disclosure of inspection reports, Jyrki Raina, general secretary of IndustriALL Global Union, said transparency is a key to success.

“The inspection reports contain an unprecedented level of detail and set a new standard in transparency and credibility. The reports provide the necessary measures for the continuous work to make the Bangladesh garment industry safe and sustainable,” Raina said in a statement yesterday.

Roy Ramesh Chandra, general secretary of IndustriALL Bangladesh Council, said they have already asked the inspection teams to be flexible and cooperative.

The Accord will disclose its findings and recommendations on its website to make information available for the public.

The legally binding agreement was signed in last May in response to a building collapse on April 24 last year that killed at least 1,135 people. The Rana Plaza building collapse exposed harsh and unsafe conditions for many of around 40 lakh workers in the garment sector.

The deal under the Accord requires brands and retailers to pay up to $500,000 per year to administer the inspection programme. On top of that, they are also responsible for ensuring that enough money is available to pay for renovations and other safety improvements.

The pact is being backed by labour groups such as the Clean Clothes Campaign and Workers' Rights Consortium. The International Labour Organisation acts as the independent chair.

Meanwhile, the Alliance for Worker Safety in Bangladesh, a platform of 27 US-based retailers and brands, are due to start inspecting 400 factories today.

For all latest news, follow The Daily Star's Google News channel.

For all latest news, follow The Daily Star's Google News channel.

Comments