Pandemic puts a damper on Tata pickup project

The initiative of Tata Motors and Nitol-Niloy Group to assemble the Indian automobile giant's specialised pickup trucks in Bangladesh has hit a roadblock as the progress of the project is being stymied by the ongoing pandemic.

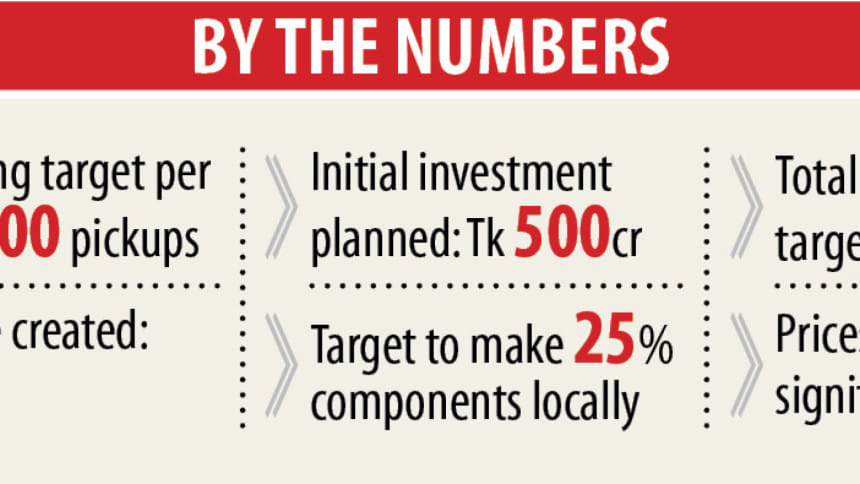

"We had set a target to start assembling pickup trucks and manufacture at least 25 per cent of the components in Bangladesh by 2020. But the pandemic has delayed our work by at least a year," said Abdul Matlub Ahmad, chairman of Nitol-Niloy Group.

"We could not carry out work at the factory as Tata's engineers and other technical officials cannot travel amid the pandemic," he added.

According to the chairman, the group initially planned to assemble 800 pickup trucks per month at a factory of Nita Company, a joint venture of Nitol-Niloy and Tata, in Kishoreganj.

Now though, they have an old plant in Jashore, where they can assemble small pickups and other trucks.

Currently, the chassis for trucks, buses and minibuses are imported in completely knocked down (CKD) condition and put together at the Jashore plant, said Ahmad.

The demand for pickup trucks in Bangladesh was over 1,000 units per month for the last four years with a growth rate of 18 per cent, data from the Bangladesh Road Transport Authority (BRTA) shows.

The BRTA approved the registration to 13,512 pickup trucks from various manufacturers in 2017, up from 11,371 in 2016, 10,257 in 2015 and 9,554 in 2014.

However, the BRTA has been unable to update these statistics amid the ongoing Covid-19 pandemic.

"We have all the machineries required at the Kishoreganj plant to start assembling as planned but unfortunately, pandemic has caused delays," said Ahmad, also a former president of the Federation of Bangladesh Chambers of Commerce and Industry, the country's apex trade body.

The end game is not just to assemble pickup trucks in Bangladesh but to spur on automobile manufacturing in the country, he added.

Ahmad also said that they originally wanted to introduce a 'made-in-Bangladesh' pickup truck by January 2021. However, the initiative has been delayed by at least one year.

"I dreamed to introduce made in Bangladesh automobiles for the country's golden jubilee but the situation is not in our favour," he said.

As per international practice, at least 25 per cent of a vehicle's components must be manufactured domestically to call it a local product.

Nitol Motors would manufacture the chassis, body, pinion, rims and brake components, which would be economically viable, Ahmad said, adding that Tata would directly supply the rest of the components to the manufacturing plant.

Nitol Motors started assembling Tata buses and trucks in 1991 and has been Tata Motors' partner since 1988.

Now, it is the largest distributor of Tata Motors in South Asia and the most dominant player in the country's commercial vehicle market with over 40 per cent of the market share.

According to Nitol Motors, it accounts for over two-thirds of the pickup truck market in the country and has been growing at a double digit rate for the past five years.

Due to delays, Ahmad said their investment would increase to Tk 500 crore from an estimated Tk 300 crore to set up an assembly plant for pickup trucks and it would need a total Tk 800 crore to manufacture trucks and buses in future.

Ahmad also said that the assembly of pickup trucks would reduce its price in the domestic market by about one third per unit.

RAB, Police and small entrepreneurs will be major customers for the pickup, he added.

"If we are able to start assembling and manufacturing at the plant, local vendors who provide us components would be beneficial, as Prime Minister Sheikh Hasina announced 'Light Engineering' as the product of the year to give special attention for earning more foreign exchange through exporting various products."

For all latest news, follow The Daily Star's Google News channel.

For all latest news, follow The Daily Star's Google News channel.

Comments