Cooling water requirement for Rooppur nuclear power plant

A nuclear power plant is an unavoidable option for Bangladesh to meet the ever increasing demand for electricity and to diminish the reliance on waning reserve of natural gas for power generation. The dream of a nuclear power plant with a capacity of only 70 MW on the roaring river Padma at Rooppur started in 1961. Now it seems to be coming true with an increased capacity of 2,000 MW, but on the dying river Padma.

Almost all the nuclear power plants in the world are built next to big water bodies like lakes and seas to ensure availability of the immensely vast amounts of cooling water needed. Plants on river banks number only 14%, and track records of a few are also not satisfactory. The effect of Rooppur Nuclear Power Plant (RNPP) on the GK project, through which water is withdrawn from Padma for surface irrigation, has also to be investigated. Cooling water is the life of a nuclear plant, and the scarcity of water may cause a major disaster.

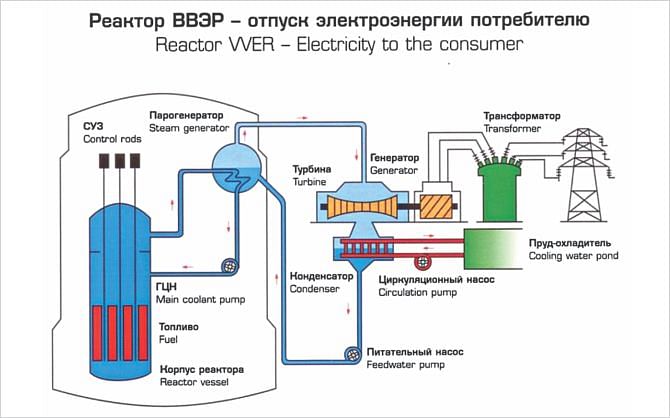

Cooling circuit of Pressurised Water Reactor PWR

The reactor that will be used in Rooppur plant has three cooling circuits -- primary, secondary, and tertiary.

A nuclear power plant is about 33% efficient. That means that out of three parts of thermal output of the reactor one part will go to the grid as electricity and two parts will go into the environment as waste heat.

Thus, for a 1,000 MWe VVER nuclear power plant, 2,000 MW of thermal energy from the reactor will be dissipated into the atmosphere. With cooling towers of range 30°F, the cooling water requirement in re-circulatory condenser water system will be approximately 455,000 gpm.

Once the condenser water system is topped up, fresh water has to be continuously added to the system to make up the losses due to evaporation, drift and blow down. Makeup water for 2,000 MWe will be 50,650 gpm, or 115 cusec approx.

The concentration of dissolved salts in the circulating condenser water should be maintained within allowable limit by blow down and refill by fresh water. Otherwise, the formation of scale inside the condenser tubes will resist heat transfer and reduce plant output. This will enforce plant shutdown to clean the scales.

Water for service equipment

There are many service equipments that need to be continuously cooled. The service water system will draw cold water from the river and circulate through service equipments and finally deliver the warm water back to the river. For 2,000 MWe, the service cooling water flow rate will be around 104,000 gpm. 230 cusec.

Water for emergency cooling of reactor

When the plant is manually stopped for an emergency or shut down for maintenance work, the radioactive decay will continue generation of heat, which has to be removed by the emergency cooling system. The decay heat is about 7% of thermal output of the reactor. The estimated flow rate of the condenser water circuit for decay heat removal is estimated to be 63,000 gpm per reactor and the total makeup water for the re-circulatory systems is 5,700 gpm. 12.7 cusec.

Failure of the emergency cooling system for want of water or power may cause reactor meltdown, leading to catastrophes similar to Chernobyl and Fukushima nuclear disasters. Apart from the flowing water of river Padma, RNPP has to store enough water for emergency purpose in reservoir tanks at the site.

Emergency service water system

The emergency service water system (ESWS) is an independent network to meet the makeup water for reactor cooling system and the cooling water for the associated emergency service equipment. The service equipment related to generation of electricity will be excluded. The cooling water requirement will be around 230 cusec. On the other hand, decay heat is produced in spent fuel rods (SFR). Water is required for continuous cooling of these spent nuclear fuels.

Availability of water in river Padma

The Padma is no more a turbulent river as it used to be. In the dry season, the river is full of chars. The main course is split into two streams at places, with char in between. Both the flow and the level of water go down drastically.

Changing its course and eroding the banks is the nature of the Padma. RNPP will require intake canals leading to a permanent intake structure near the plant for pumping of water. The dredging in intake canals may warrant shutdown of the plant.

It is found from Bangladesh Water Development Board's data that the mean minimum flow over the last twelve years is 632 cumsec (22,300 cusec), which may allow withdrawal of around 345 cusec of makeup water needed for operation of the plant. But an abrupt reduction of flow to only 3,100 cusec, as in May 2011, will pose a threat to safety of the plant. There is no reason to believe that such an abnormal reduction of flow will not occur in future, and if it does then RNPP will be compelled to shut down because of scarcity of water.

Water management will be the major challenge, especially in dry season. The intake structure for pumping of water has to be carefully designed and built to be workable at high water level in monsoon as well as much lower water level in dry season.

Quality of river water

During monsoon the river Padma carries huge amount of silt and sand and the water is muddy with suspended solids. This alluvial dirty water is not suitable for direct introduction to condenser cooling water system because the suspended solids will settle in the condenser tubes and impede heat transfer. The remedy will require large decantation ponds to allow the suspended solids to settle down and give clear water for the cooling system.

Experience of GK irrigation project

The GK (Ganga-Kabotakh) project is situated on the other bank of the river at Bheramara. The project is handicapped due to withdrawal of water by Farakka barrage. The nominal capacity of the pumping station is 153 cumsec (5,400 cusec) but only 70% of designed capacity can be achieved. The problems faced by the project are given below:

1) The project totally failed to supply water during 1992-1996 for non- availability of water.

2) The pump-house is shut down in dry season (mid-Nov to mid-March).

3) The pumps cannot operate if water level in intake station is less than 4.5 m.

4) 186,000 cubic meters of silt needs to be dredged annually from the 850 m intake channel.

The planners of RNPP can consider the above as cautionary signals to take appropriate measures.

Conclusion

A nuclear power plant is a thirsty creature with insatiable need for cooling water. The river Padma has to be able to satisfy the thirst under any circumstances. How a project can be made sustainable when it depends on river water whose flow is regulated by a barrage in another country is the question.

The writer is a Senior Mechanical Engineer.

E-mail: [email protected]

Note: The interested reader may contact the writer for supporting calculations.

For all latest news, follow The Daily Star's Google News channel.

For all latest news, follow The Daily Star's Google News channel.

Comments